- Molded Heat Insulating Material

- Soft Felt

- C/C Composite (CCM®)

- Carbon fiber packing materials (CARBEST®)

Molded Heat Insulating Material

Felt Molded heat insulating material series FGL is usable in high temperature up to more than 2000 degrees Celsius, and it excels in insulation and workability. High purity treatment product is the most suitable item as a furnace material which doesn't accept impure substance.

Usage

A range of Heat insulators for high temperature furnaces

-

Item Number

-

Typical Characteristic

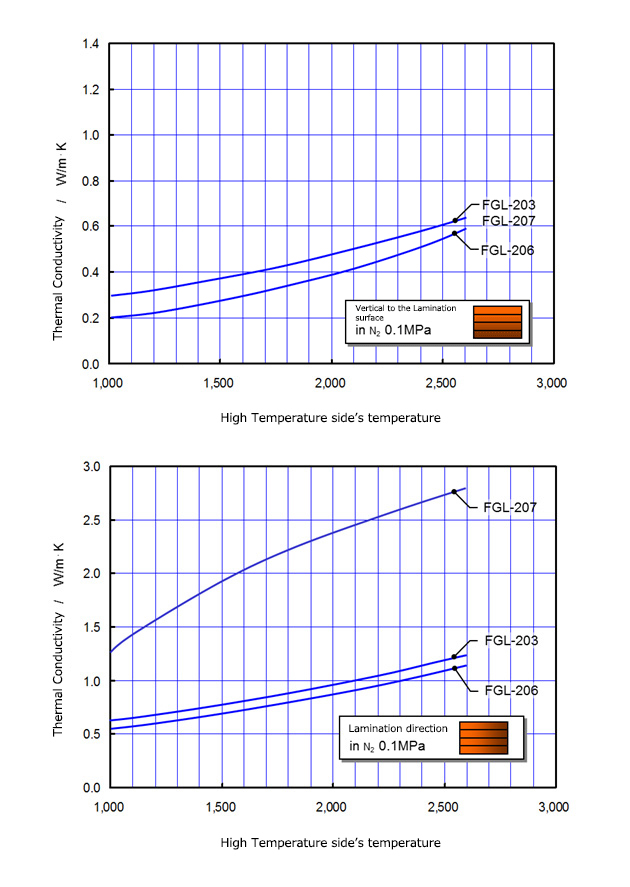

Article Unit FGL-203 FGL-206 FGL-207 Bulk Density g/cm3 0.16 0.10 0.16 Electrical resistivity mΩ・cm (⊥)450 (⊥)900 (⊥)3200 (//)100 (//)180 (//)45 Bending Strength (1) MPa 0.5 - 1.1 Compressive Strength (2) MPa 0.3 - 0.3 Thermal Expansion Coefficient (3) ×10-6/K 2 2 2~3 Thermal Conductivity (4) 1500℃ W/(m・K) 0.38 0.28 0.38 2000℃ 0.48 0.40 0.48 2500℃ 0.61 0.55 0.61 Ash content For High Temperature Furnaces ppm 300~800 Actual Standard High Purity Product Lower than 200 (Guaranteed Value),

50~70 (Actual Standard Value)Super High Purity Product Lower than 50 (Guaranteed Value),

10~20 (Actual Standard Value)Surface Treatment Cloth Lining Yes - Yes Graphite Coating Yes - Yes Graphite Foil Lining Yes - Yes

1) Bending Strength

Indicates a strength value when pressure is applied toward a lamination angle and vertically.

2) Compressive Strength

Indicates a strength value when pressure is applied toward a lamination angle and vertically.3) Thermal Expansion Coefficient

Indicate a representative value measured between chamber temperatures up to 500 degrees Celsius.4) Thermal Conductivity

Indicate a measurement value in N2-0.1MPa, following the steady heat flux correction method.- *These are representative values, not guaranteed values.

-

Thermal Conductivity

-

Surface Treatment

FGL-207

FGL-207G

Graphite Coat

- Dust Generation Prevention

FGL-207C

Carbon Cloth LiningFGL-207F

Graphite Foil Lining

- Dust Generation Prevention

- High Strength

- Surface Protection

- Dust Generation Prevention

- Low Gas-permeability

- Surface Protection

-

Maximum Size

Purity Shape Largest Integrally Formed Size Standard Product Plate 2,200 (width) × 2,200 (length) × 200 (thickness) Cylinder 2,200 (external diameter) × 1000 (height) High Purity Product Plate 2,200 (width) × 2,200 (length) × 200 (thickness) Cylinder 2,200 (external diameter) × 1000 (height) Cylinder higher than 1,000 mm are producible by diveded pieces with special method.

Soft Felt

Lightweight and flexible CARBORON® felt has high heat insulation, providing an optimum substance for high temperature furnace material.

Usage

A range of Heat insulators for high temperature furnaces

-

Item Number

-

Typical Characteristic

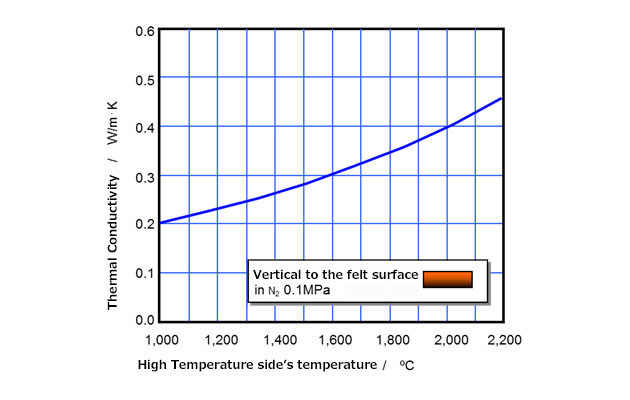

Characteristics Unit GF-20 Thermal Conductivity* 1,000℃ W/(m・K) 0.20 1,500℃ 0.28 2,000℃ 0.40 Electrical resistivity Ω・cm 0.15 - 0.20 Bulk Density 0.10g/cm3 0.08 - 0.10 Carbon Containment Percentage % > 99 Water Absorbability % < 0.1 - *These are representative values, not guaranteed values.

-

Thermal Conductivity

-

Representative Size

Article Thickness Basis Weight Representative Width Maximum Length Unit mm g/m2 mm m GF-20- 5F 4.5 470 1,000 32 GF-20- 7F 6.5 770 16 GF-20- 10F 9.5 1,050 GF-20- 12F 12.7 1,100

- * CARBORON® is a registered trademark of Nippon Carbon Co., Ltd.

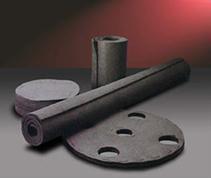

C/C Composite (CCM®)

Usage

Heat Resistant Composite Structural Members, Various High Temperature Furnace Materials, Trays, Jigs etc.

Square Pipe

Angle

Dice

Tray

Pipe

Pipe

Spring

Heater

Base Tray

Bolt

Bolt

Crucible

-

Item Number

-

Structure and Characteristics

Item Number CCM™-190C CCM™-400C Structure Surface

Cross-Section Surface

Characteristics Lightweight

High Bending Strength

High Heat Resistance

Thermal shock Resistance

High Conductivity

Excellent Chemical Corrosion ResistanceHigh Tensile Strength

High ElasticityIn-plane Isotropy

High Shear Strength

Precise Machinability

-

Typical Characteristic

Characteristics Unit CCM-190C CCM-400C Reinforced Fibers ‐ Continuous Fiber Chopped Fiber Fiber Orientation ‐ 0º / 90º Two-Dimensional Random Bulk density g/cm3 1.60 1.45 Bending Strength MPa 160 140 Bending Coefficient of Elasticity GPa 65 35 Tensile Strength MPa 260 95 Tensile Coefficient of Elasticity GPa 80 45 Compressive Strength MPa 90 90 Interlayer Shear Strength*1 MPa 6 12 Shore Hardness ‐ 70 80 Electrical Resistivity*2 ×10-6Ω・cm 2200 2300 Thermal Expansion Coefficient*3 ×10--6K (//)0.2 (//)0.4 (⊥)5.7 (⊥)9.0 Thermal Conductivity*2 W/(m・K) (//)27 (//)23 (⊥)4 (⊥)17 Shape Plate

Tube

Bolt & Nut

Abnormal Profile Product

Crucible

Angle, ChannelPlate

Bolt & Nut*1 Uneven Notch Test Piece Compressing Method

*2 Measured at the chamber temperature

*3 Average thermal expansion coefficient measured between chamber temperatures up to 800 degrees Celsius.

(//) Parallel to the fiber

(⊥) Vertical to the fiber- *These are representative values, not guaranteed values.

- * CCM® is a registered trademark of Nippon Carbon Co., Ltd.

Carbon fiber packing materials (CARBEST®)

-

Item Numbers and Descriptions for CARBEST®Products

- * CARBEST® is a registered trademark of Nippon Carbon Co., Ltd.

Other Products Information

Adobe Reader ® is required to view PDF files.