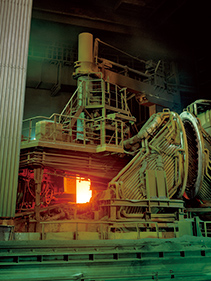

The technological development of recent electric arc furnaces has been dramatic, as represented by D.C. (Direct Current) furnaces which have seen the capacity enlargement of both the furnace and transformer allowing us to use higher currents and hence higher powers which enables us to achieve a much higher level of productivity. Since successfully making the first ever artificial graphite electrode in Japan in 1927, we at Nippon Carbon have worked to develop and produce our artificial graphite electrodes to be more mechanically robust and stronger against thermal impacts, so as to meet the tough conditions within high-power electric arc furnaces. At present, we are providing 32” (816mm) diameter ultra-high-power electrodes, the largest in the world.

Nippon Carbon's artificial graphite electrodes are acknowledged for their high quality, being used around the world.

Nippon Carbon's artificial graphite electrodes are acknowledged for their high quality, being used around the world.

Details of Artificial Graphite Electrodes

Refer to the following PDF file.

Standard Dimensions / Weight (PDF:460KB)![]()

Nippon Carbon Partners with TMS

Nippon Carbon and TMS have had a longstanding business relationship and TMS will be the exclusive marketer of Nippon Carbon’s graphite electrodes in North America. TMS will assist in helping to expand Nippon Carbon’s footprint in North America. TMS is a natural partner in this venture since the company has a robust global trading network while being onsite at more than 80 graphite electrode user sites throughout the world.

Other Products Information

Adobe Reader ® is required to view PDF files.